DIRCOM PROCESS

Neue Materialien Fürth GmbH

In the past, several research groups have made considerable efforts in developing a suitable casting process for short-fibre- and particle-reinforced materials (metal matrix composites – MMC) based on the incorporation of the reinforcing material by stirring with subsequent die casting. Various problems occured, however, such as the formation of agglomerates, settling of the reinforcing phases, the development of gas porosity and strong reactions between molten alloy and reinforcing phase.

Neue Materialien Fürth GmbH, started working on a new, better suited process chain. Several years ago, with the construction of a prototype magnesium extruder (compounder) for incorporating the reinforcing phase into magnesium alloys.

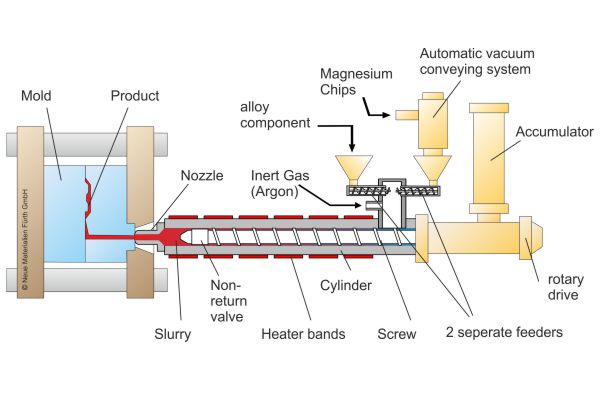

Within the publicly funded THIXOM project, the production route was further developed joining the extruder with a die casting unit to create a new, single-stage casting machine. This innovative direct compounding (DirCom-) process is intended to combine the benefits of injection molding and die casting.

Project partners were Volkswagen AG, Reiloy Metall GmbH, GK Concept GmbH and Druckguss Service Deutschland GmbH, as well as the Institute of Lightweight Engineering and Polymer Technology (ILK, TU Dresden) and the Helmholtz-Zentrum Geesthacht – Zentrum für Material- und Küstenforschung GmbH (Centre for Materials and Coastal Research).

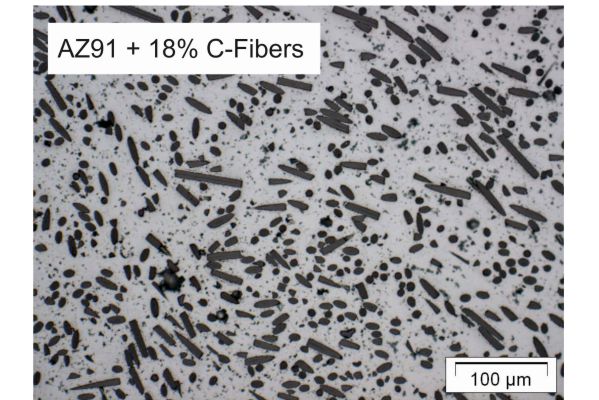

Example of the microstructure of the AZ91 alloy with a carbon fibre content of 18 vol% after compounding

Direct compounding prototype system at NMF

This research and development project was funded by the German Federal Ministry of Education and Research (BMBF) within the Framework Concept "Innovations for the production, service and work of tomorrow" programme (funding codes 02PJ2790 – 02PJ2796) and managed by the Project Management Agency Forschungszentrum Karlsruhe, Production and Manufacturing Technologies Division (PTKA-PFT). Responsibility for the content of this published information lies with its authors.

ABOUT US

Neue Materialien Fürth GmbH (NMF) is a national research center of the Bavarian State. We transform cutting-edge materials and manufacturing methods into industrial solutions. Our 3000 m² testing field is equipped with large-scaled industrial facilities. The scope of our work is not limited to research – we also manufacture prototypes and small batches.

Neue Materialien Fürth GmbH is linked with Neue Materialien Bayreuth GmbH and the University of Erlangen (Universität Erlangen/FAU).

You will find us at Dr.-Mack-Straße 81 in 90762 Fürth,

or simply let yourself be guided by Google Maps.

Contact

Funding

Neue Materialien Fürth GmbH is institutionally funded by: