Alloy development

Neue Materialien Fürth GmbH

AZ91 and AM60 are the alloys predominantly used today for the large-scale production of magnesium components. AZ91 is mainly used due to its good strength at room temperature while AM60 is beneficial when high ductility is needed. However depending on the application these alloys cannot fulfill all demands. In some cases, for example, higher ductility, improved creep strength or higher thermal conductivity are required.

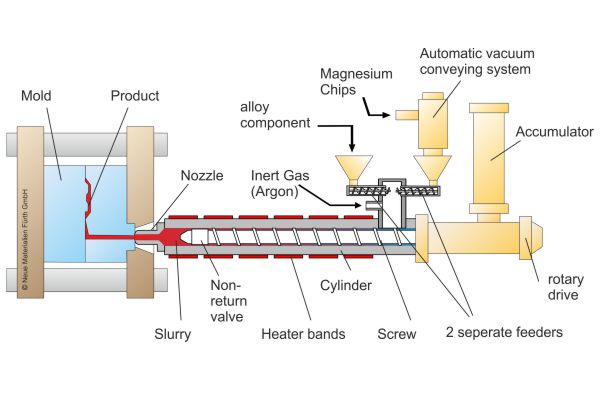

Neue Materialien Fürth GmbH has improved the magnesium injection moulding process specifically for the purpose of developing alloys. Using a patented dosing system, most alloying elements can be added to the master alloy as granules.

Continuous shearing of the material in the screw ensures intensive mixing of the alloying components and therefore a uniform distribution of the elements.

The diagram shows a magnesium injection moulding system with two metering units ("feeders") for alloy development.

This method offers a quick way for evaluating the properties of a wide range of different alloy compositions using typical cast components. Up to now a large number of different alloys have been investigated at NMF. Depending on the application the alloys are characterized concerning e.g. the microstructure, the mechanical properties at elevated temperature or the castability.

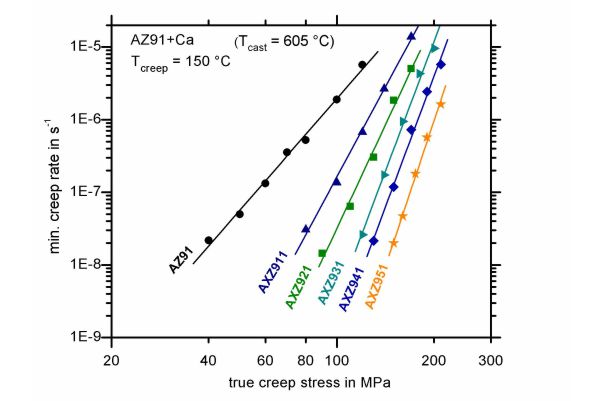

For example the influence of adding Strontium to AZ91 concerning the creep resistance has been studied. The diagram illustrates the significant improvement of the creep rate.

For the development of short-fibre- and particle-reinforced magnesium materials, we will be able to use our brand new DirCom-process from now on.

ABOUT US

Neue Materialien Fürth GmbH (NMF) is a national research center of the Bavarian State. We transform cutting-edge materials and manufacturing methods into industrial solutions. Our 3000 m² testing field is equipped with large-scaled industrial facilities. The scope of our work is not limited to research – we also manufacture prototypes and small batches.

Neue Materialien Fürth GmbH is linked with Neue Materialien Bayreuth GmbH and the University of Erlangen (Universität Erlangen/FAU).

You will find us at Dr.-Mack-Straße 81 in 90762 Fürth,

or simply let yourself be guided by Google Maps.

Contact

Funding

Neue Materialien Fürth GmbH is institutionally funded by: