Mould design/process simulation

Neue Materialien Fürth GmbH

Neue Materialien Fürth GmbH uses computer-aided geometry and process design methods for casting light metal components. Magnesium injection moulding, die casting aluminium/magnesium and the associated mould design are amongst the primary applications of these methods. The aim of simulating the casting process is to devise the optimal part design quickly, to design the casting system and to identify and use the most appropriate process parameters.

MOULD DESIGN AND PROCESS SIMULATION:

APPLICATIONS AND ADVANTAGES

- Optimised component production

- All casting processes simulated

- Fast, optimal part design

- Casting system design

- Ideal process parameters can be identified and used

- Current computer-aided methods

MOULD DESIGN AND PROCESS SIMULATION:

HOW IT IS DONE

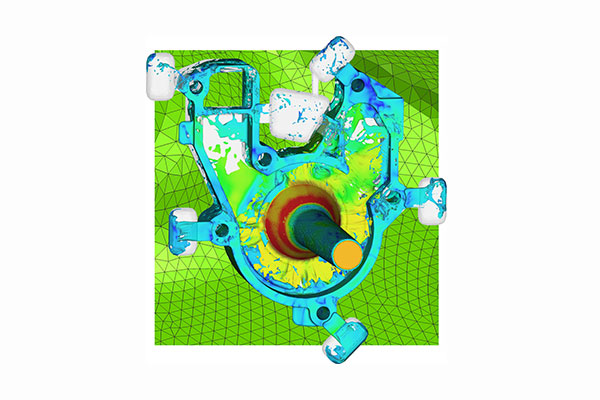

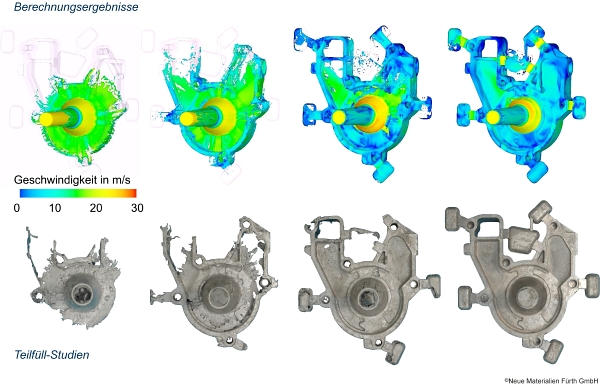

Computations are performed to simulate how the mould is filled and how the component solidifies. The mould filling is based on a cycle calculation that simulates the inhomogeneous thermal state of the mould. To assess the process design that has currently been selected, our experts ascertain the likelihood of casting defects occurring. When doing so, NMF GmbH considers defects that occur when the mould is filled like e.g. entrapped air, as well as shrinkage cavities and pores that form as the material solidifies.

If simulations are to be used to optimise the production of components, it is incredibly important to obtain high-quality results. The adjacent images of a die cast component being poured into a mould illustrate that reliable results are completely achievable. The computed mould filling is consistent with partial filling test results obtained by experimentation.

ABOUT US

Neue Materialien Fürth GmbH (NMF) is a national research center of the Bavarian State. We transform cutting-edge materials and manufacturing methods into industrial solutions. Our 3000 m² testing field is equipped with large-scaled industrial facilities. The scope of our work is not limited to research – we also manufacture prototypes and small batches.

Neue Materialien Fürth GmbH is linked with Neue Materialien Bayreuth GmbH and the University of Erlangen (Universität Erlangen/FAU).

You will find us at Dr.-Mack-Straße 81 in 90762 Fürth,

or simply let yourself be guided by Google Maps.

Contact

Funding

Neue Materialien Fürth GmbH is institutionally funded by: