Production of tailored semi-finished parts

Neue Materialien Fürth GmbH

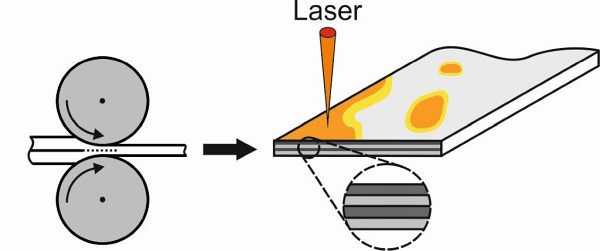

Taking the complete process chain into account, we manufacture multilayered sheet metals with tailored properties using our four-high rolling machine.

Amongst others, the Accumulative Roll Bonding process is used for the production of sheets with, for example, 256 layers and a significantly enhanced mechanical strength. Furthermore, this process enables the combination of different metals and alloys and thus the production of sheet metals with tailored property gradients.

In addition, hybrid sheet materials with internal polymer layers are produced by means of warm rolling. The combination with the Tailor Heat Treated Blanks technology enables the enhancement of the formability of these materials applying a local short-term heat treatment using laser radiation.

ABOUT US

Neue Materialien Fürth GmbH (NMF) is a national research center of the Bavarian State. We transform cutting-edge materials and manufacturing methods into industrial solutions. Our 3000 m² testing field is equipped with large-scaled industrial facilities. The scope of our work is not limited to research – we also manufacture prototypes and small batches.

Neue Materialien Fürth GmbH is linked with Neue Materialien Bayreuth GmbH and the University of Erlangen (Universität Erlangen/FAU).

You will find us at Dr.-Mack-Straße 81 in 90762 Fürth,

or simply let yourself be guided by Google Maps.

Contact

Funding

Neue Materialien Fürth GmbH is institutionally funded by: