Powder metallurgy

Neue Materialien Fürth GmbH

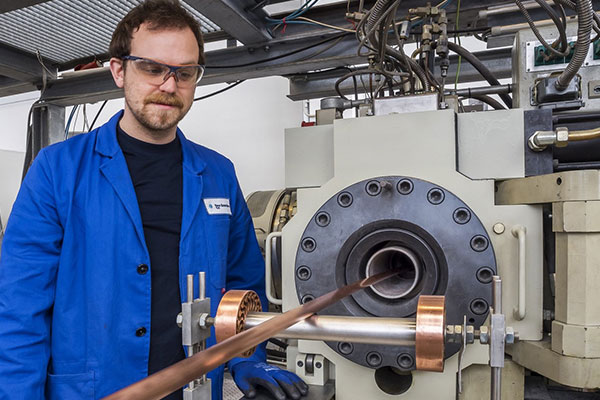

The new Temconex® technology developed by Neue Materialien Fürth GmbH involves continuous powder extrusion. In a cost-effective single-step process, metal powders are transformed directly into dense wires or profiles.

The basis of the Temconex® process is the ConformTM process. Unlike the ConformTM process, powder is used as the feedstock, rather than continuous cast wire rod. Moreover, the systems have undergone significant modification; in particular, they now feature a special tool cooling and heating system (Temconex® technology = temperature controlled continuous extrusion) .

The Temconex® process is considerably more cost-effective than the conventional extrusion press process for consolidating powders. It also allows chips to be processed. The Temconex® method yields advantages over traditional metal melting processes for difficult-to-process metals, very thin wires and complex profiles.

Furthermore, at NMF, we can use a roller compactor to transform the bulk material into granules before commencing the Temconex® process. This binder-free dry agglomeration increases productivity and reduces the risk of explosions and reactions.

DOWNLOADS

Contacts

Team leader:

Dr.-Ing. Wolfgang Böhm

Scientific leadership:

Prof. Dr.-Ing. habil. Marion Merklein

Contact: temconex@nmfgmbh.de