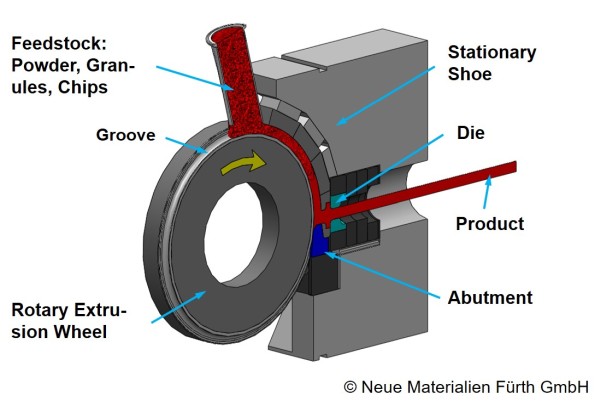

Temconex® process

Neue Materialien Fürth GmbH

In the continuous powder extrusion pressing process (Temconex® process), the powder is fed into the groove that runs all the way round a rotating extrusion wheel. The powder is transported in the wheel's direction of rotation by friction. A stationary die holder covers part of the extrusion wheel. Between them, these two components create an extrusion chamber in which the material that is fed in is compacted, and heated by friction and shearing. A counterpiece that protrudes into the groove terminates the chamber.

The material flow is diverted around this obstacle in such a way that it accumulates just in front of the die. Once the material reaches its yield point, it is extruded through the die radially with respect to the extrusion wheel.

ADVANTAGES OF Temconex® technology:

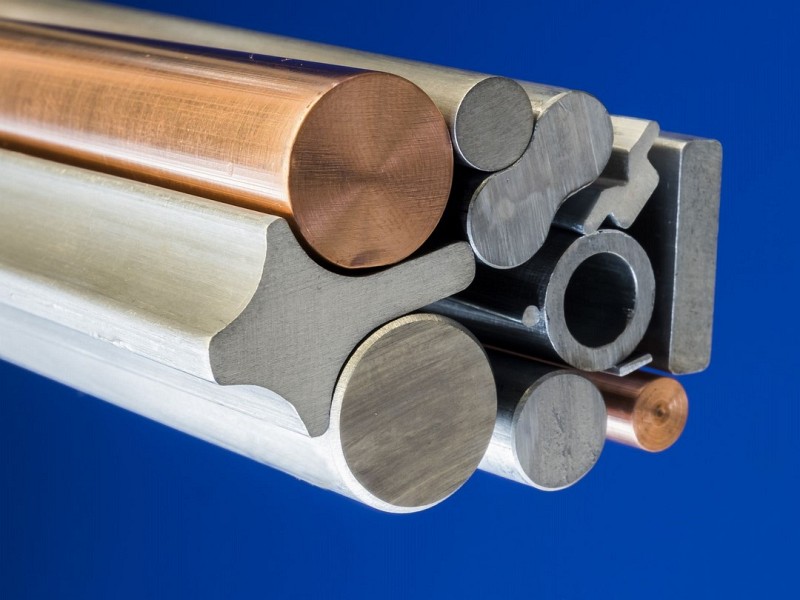

- Wide range of materials, including aluminium, copper, silver and their alloys

- Composites (MMCs) can be processed

- Variety of feedstock geometries from powder to granules

- Chips can be recycled

- Variety of final geometries from wires and profiles to rods and piping

- Excellent surface quality

- Fully compacted end product with outstanding mechanical properties

- High material and energy efficiency

- Short process chain with high level of automation

- Forming to achieve the final geometry in a single step

ABOUT US

Neue Materialien Fürth GmbH (NMF) is a national research center of the Bavarian State. We transform cutting-edge materials and manufacturing methods into industrial solutions. Our 3000 m² testing field is equipped with large-scaled industrial facilities. The scope of our work is not limited to research – we also manufacture prototypes and small batches.

Neue Materialien Fürth GmbH is linked with Neue Materialien Bayreuth GmbH and the University of Erlangen (Universität Erlangen/FAU).

You will find us at Dr.-Mack-Straße 81 in 90762 Fürth,

or simply let yourself be guided by Google Maps.

Contact

Funding

Neue Materialien Fürth GmbH is institutionally funded by: