Digitalization

Digitalization in production technology

An increasingly networked production in the sense of industry 4.0 allows completely new possibilities regarding an improved and more efficient production quality. With Blockchain technology, Artificial Intelligence and Augmented Reality, production processes can be made safer and more transparent and production quality significantly increased.

Blockchain can lead to increased robustness and increased efficiency in production. Due to their complexity and low buffer stocks, today's production networks are susceptible to unexpected disruptions such as a supplier failure. In this scenario a quick and complete overview of the delivery capability of the remaining suppliers and their available stocks is required in order to coordinate alternative procurement channels as quickly as possible. Through Blockchain this required transparency can be achieved by means of comprehensive real-time information, when all suppliers write their information about production progress and stocks into the Blockchain. In addition, there is the opportunity to systematically track individual parts through the production network.

Neue Materialien Fürth GmbH offers industry-oriented solutions to integrate Blockchain technology quickly and easily into existing processes and to improve production processes:

- Workshop Fundamentals of Blockchain technology

- Consultation about Blockchain technology in the manufacturing industry

- IT services and technical implementation of the Blockchain technology

Blockchain

Securely connected production processes

Advantages for industrial use:

- Tamper-proof exchange of process- and product-relevant data

- Data traceability from final product back to semi-finished product

- Specification and release of processes

Augmented Reality

Interactive comparison of simulation and component

Benefits for industrial use:

- Comparison of component and simulation directly on the press

- Easy visualization with iPhone and iPad

- Presentation of tools directly in the press

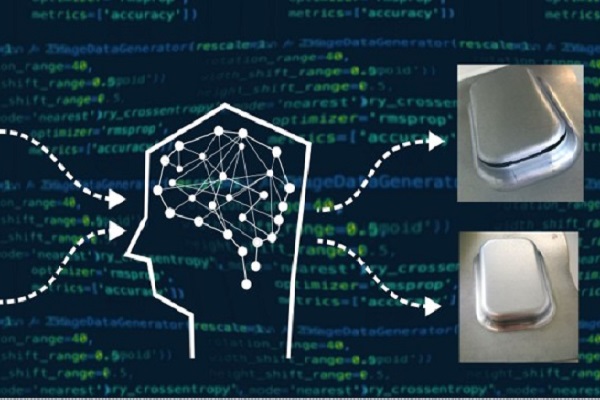

Artificial Intelligence

Automated quality assessment and 100 % inline inspection

Benefits for industrial use:

- Automated identification of faulty components in the production process

- Simple implementation in quality assurance

- Robust against variable exposure situations and crack shapes

DOWNLOADS

Contacts

Team leader:

Dr.-Ing. Wolfgang Böhm

Scientific leadership:

Prof. Dr.-Ing. habil. Marion Merklein

Contact: digitalisierung@nmfgmbh.de